Bearings in Gloucester

- Fast delivery across the Mid North Coast

- Stocked with trusted, quality brands

- Knowledgeable, hands-on customer support

Request a call back In Gloucester

Thank you for contacting Mid Coast Bearing Centre.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

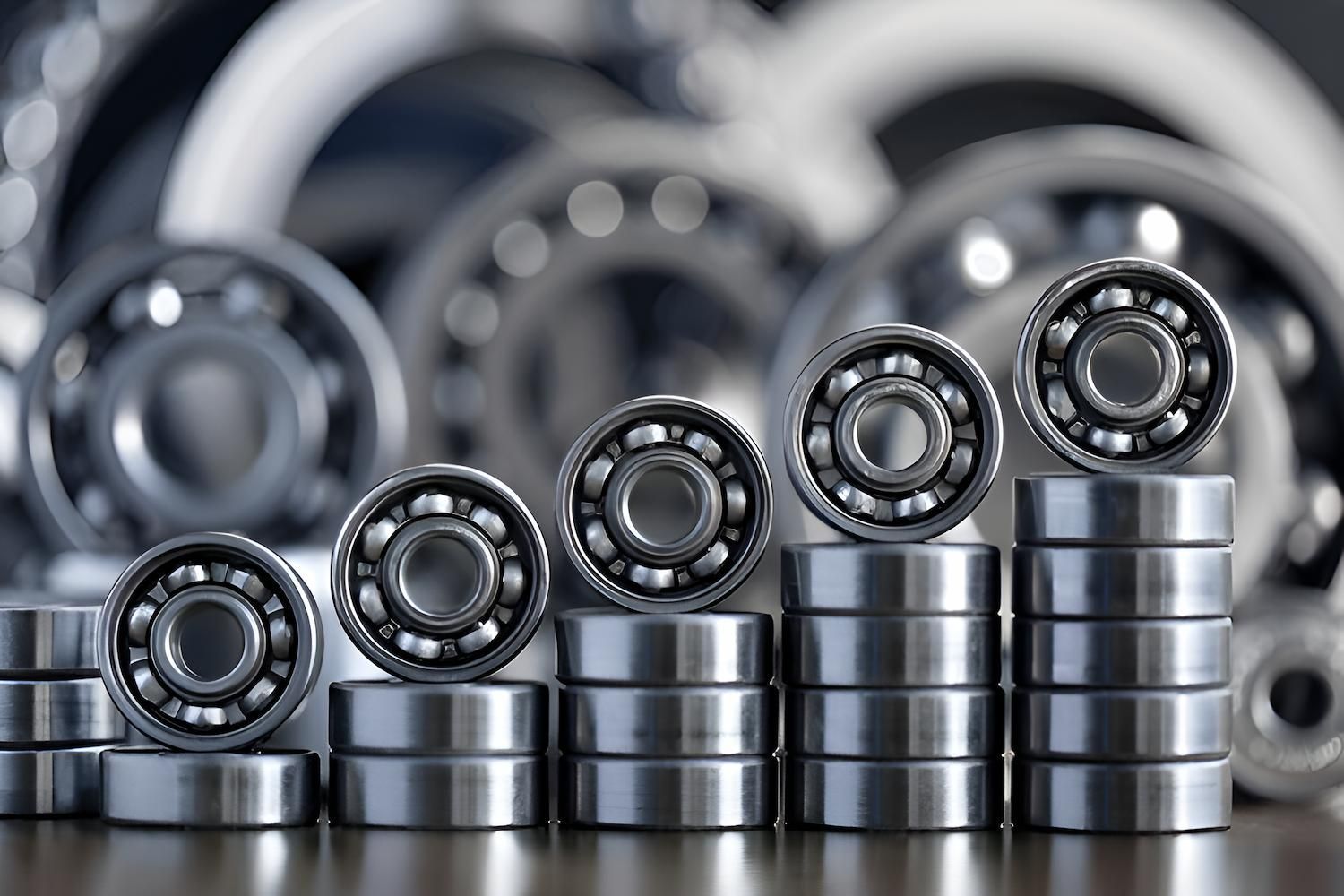

Gloucester Bearings

If you're searching for dependable bearings in Gloucester, Mid Coast Bearing Centre is your trusted local supplier. With over 40 years of industry experience, we provide reliable support to farmers, tradies, mechanical workshops, and industrial operators across the Mid North Coast.

Our team knows the importance of sourcing the right bearings—fast—and we’re committed to helping Gloucester locals keep their equipment moving. We stock a wide range of bearings, including taper, needle, plain, and linear bearings, suitable for everything from farm machinery and vehicles to factory equipment and tools.

Each product is carefully selected for durability, performance, and load-handling capacity, backed by brands you can trust. We’re known for our friendly service, in-depth product knowledge, and genuine care for our customers. Whether you're fixing a breakdown or planning preventative maintenance, we’re ready to help.

For expert service and fast supply, contact Mid Coast Bearing Centre today at 02 6552 3699—your Gloucester bearings specialist.

Smooth, Reliable Performance

At Mid Coast Bearing Centre, we help Gloucester customers avoid costly delays by supplying quality bearings tailored to their specific needs. Whether you're running a farm, managing a workshop, or operating industrial machinery, our team understands the conditions you work in and the equipment you rely on.

We take the time to ensure each bearing fits perfectly and performs well under pressure—no guesswork, no compromises. Our range is suitable for high-speed, heavy-load, and harsh environment applications, and we’re always happy to explain technical specs in plain English.

What sets us apart is our hands-on approach: you’ll speak to someone who knows their products and genuinely wants to help. If we don’t have it in stock, we’ll do our best to source it quickly and get it delivered to your door in Gloucester.

We also offer support for troubleshooting recurring issues, so you can make confident, informed decisions. When it comes to bearings, we keep it simple, practical, and fast.

What are the signs of worn or failing bearings?

Worn or failing bearings often produce tell-tale symptoms such as grinding, humming, or squealing noises during operation. You may also notice vibration, excess heat around the bearing housing, or reduced machine performance. In rotating machinery, you might see shaft misalignment or increased friction, which can lead to greater energy consumption or unexpected shutdowns. Over time, worn bearings can cause damage to nearby components, resulting in more expensive repairs. Regular inspection and early replacement can prevent these issues and keep your equipment operating efficiently.

How do I know which type of bearing I need?

To select the right bearing, consider the type of load (radial, axial, or both), the speed of rotation, space constraints, and the operating environment. For example, tapered bearings are ideal for handling combined loads, while needle bearings are great for applications with limited space. Plain bearings work well for low-speed, high-load applications, while linear bearings are used when motion along a straight path is required. Environmental factors like dust, moisture, or extreme temperatures may require sealed or shielded bearings. Always consult your equipment manual or speak with an expert to ensure proper fit and function.

How often should bearings be lubricated or maintained?

Lubrication frequency depends on the type of bearing, its application, speed, and operating environment. Bearings in high-speed or high-temperature applications may need lubrication more frequently than those in low-stress conditions. In general, it's good practice to inspect and lubricate bearings during routine maintenance intervals—this might be weekly, monthly, or seasonally, depending on usage. Over-lubricating can be just as harmful as under-lubricating, potentially causing heat build-up or seal failure. Using the correct lubricant type and amount helps extend bearing life, improve performance, and prevent unexpected failures.