Sprockets & Chains in Wauchope

- Fast delivery across the Mid North Coast

- Stocked with trusted, quality brands

- Knowledgeable, hands-on customer support

Request a call back In Wauchope

Thank you for contacting Mid Coast Bearing Centre.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

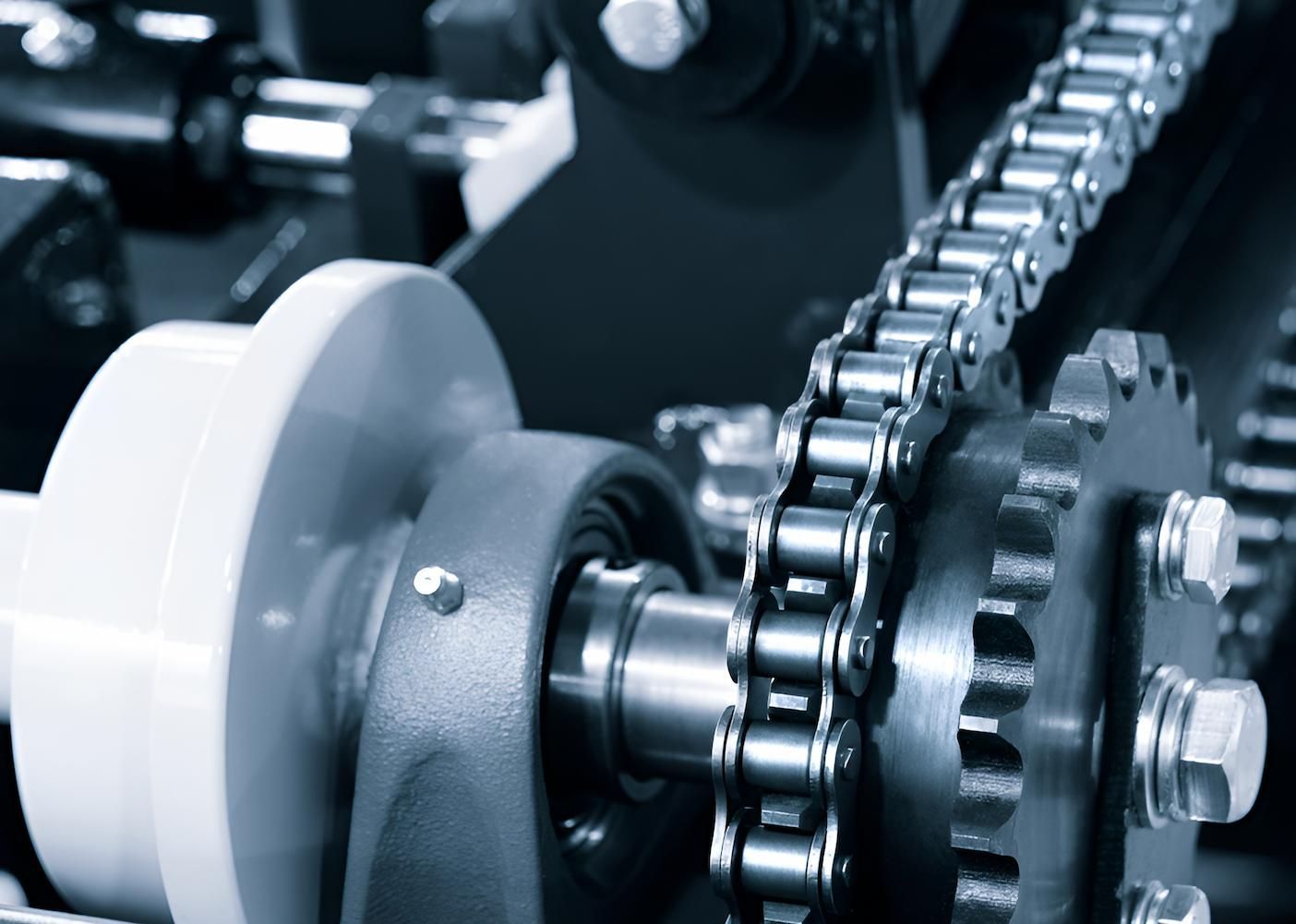

Wauchope Sprockets & Chains

Mid Coast Bearing Centre supplies dependable chains and sprockets in Wauchope, helping local operators keep machinery running reliably and efficiently. With more than 40 years of experience behind us, we offer tailored product support for everyone from farmers and earthmovers to industrial technicians and tradespeople.

Our stock includes a wide range of roller chains, stainless steel options, and heavy-duty links to suit high-torque and precision drive applications. We also carry matching sprockets to ensure correct engagement and efficient power transmission.

Whether you're replacing worn components or setting up a new drive system, we’ll help you select the right size, pitch, and configuration. All our chains are sourced from quality brands known for performance under pressure.

Wauchope customers rely on us for fast service, practical advice, and expert assistance with everything from fitment to troubleshooting. For local supply and support, call our friendly team at 02 6552 3699 and ask about our full range of chains and sprockets.

Unmatched Performance Every Time

Mid Coast Bearing Centre offers more than just chains—we deliver drive solutions tailored to Wauchope’s working conditions. Our team helps identify the correct chain type, load capacity, and tensioning system for your machinery, so you get maximum output and minimum downtime.

We stock ANSI and ISO standard roller chains, corrosion-resistant finishes for outdoor or washdown environments, and heat-treated sprockets designed for long-term wear resistance. Every component is selected to ensure compatibility and longevity, whether it’s for agricultural equipment, conveyors, or small engines.

We also provide chain breaker tools, connecting links, and expert advice on alignment and lubrication. If you’re dealing with chain slippage, elongation, or tooth wear, we’ll walk you through the best repair or replacement options.

Wauchope locals choose us because we combine hands-on experience with responsive service and fast access to parts. From custom lengths to specialist systems, we’re here to help you get your job done right.

What’s the difference between single-strand and double-strand chains?

Single-strand chains have one row of rollers and are commonly used in light to medium-duty applications, such as conveyors, motor drives, and farm equipment. Double-strand chains, also known as duplex chains, have two rows of rollers running in parallel, offering greater strength and load-bearing capacity. They’re ideal for high-torque applications where space allows, and they provide smoother operation under load. Choosing between them depends on your machinery's torque requirements, speed, and available space. Always check the sprocket compatibility when upgrading or replacing chain types, as they must match the number of strands and pitch.

How can I prevent chain elongation in machinery?

Chain elongation is typically caused by pin and bushing wear due to poor lubrication, contamination, or overloading. To minimise elongation, ensure your chain is properly lubricated with the correct oil or grease, especially at the contact points between pins and bushings. Use chain guards or covers to protect from dust, water, and debris that accelerate wear. Keeping chain tension within manufacturer-recommended limits also helps reduce strain. If your system sees heavy use or operates in dirty environments, consider using pre-lubricated or sealed chains, which offer longer service life. Regular inspections and tension adjustments are key to early detection and prevention.

What’s the proper way to align a sprocket and chain system?

Proper alignment between your chain and sprockets is critical for smooth operation and long service life. Start by ensuring the shafts are parallel and that sprockets are mounted securely with equal axial positioning. Use a straightedge or laser alignment tool across the sprockets to check for lateral alignment. The chain should run smoothly without binding or rubbing against sprocket edges. Also, verify that the chain tension is correct—not too tight or too loose. Misalignment causes uneven wear on both chain and sprocket teeth, increases noise, and can lead to premature failure. Accurate installation protects both components and improves overall efficiency.