Sealant in Wauchope

- Fast delivery across the Mid North Coast

- Stocked with trusted, quality brands

- Knowledgeable, hands-on customer support

Request a call back In Wauchope

Thank you for contacting Mid Coast Bearing Centre.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

Wauchope Sealant

When you need a reliable sealant in Wauchope, Mid Coast Bearing Centre has the products and experience to help you get the job done right. With over four decades of supply experience across industrial, automotive, agricultural, and commercial sectors, we understand the importance of choosing the right sealant for long-lasting results.

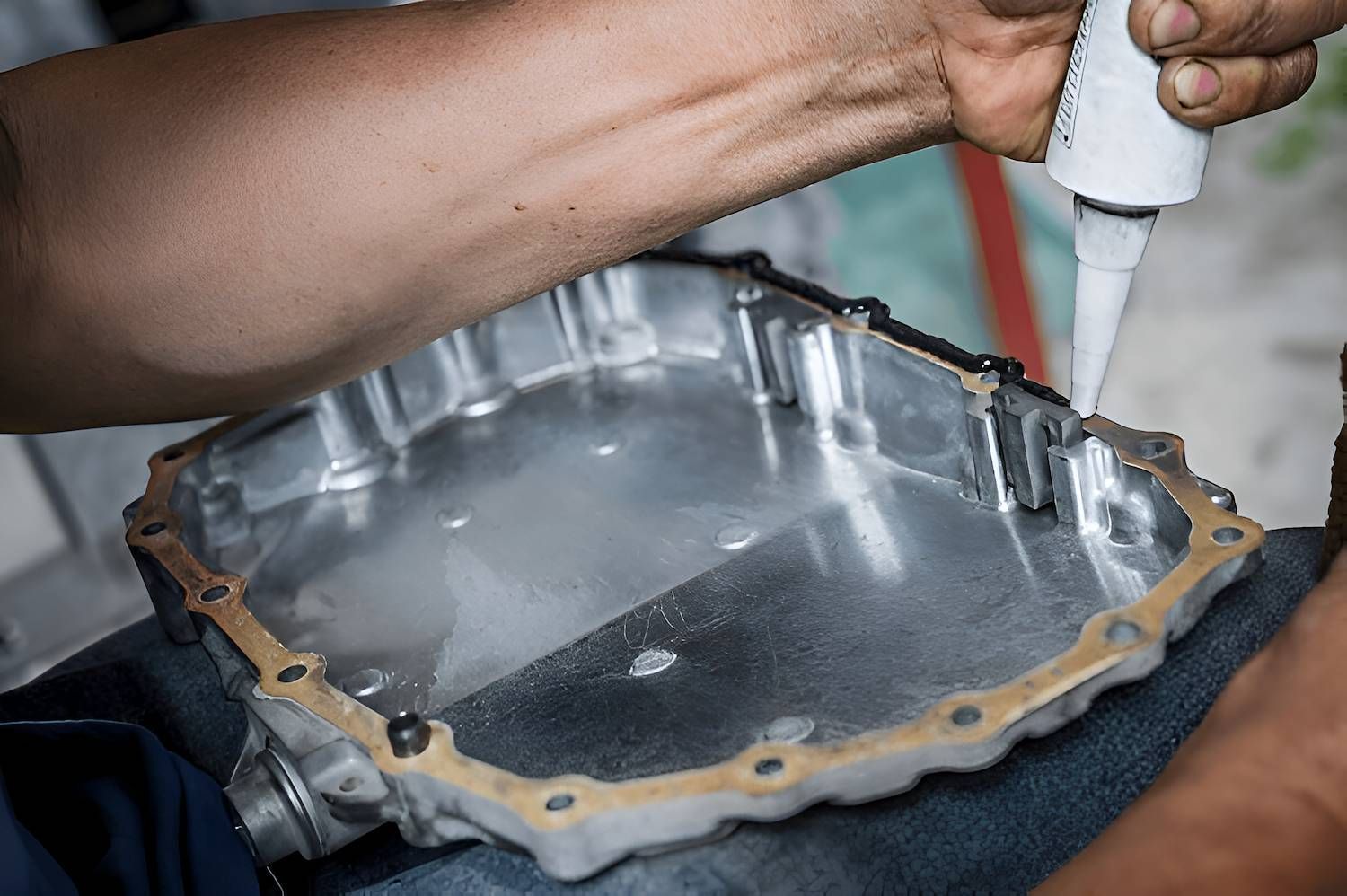

Whether you're sealing engine components, joining metal surfaces, preventing oil leaks, or bonding parts in machinery, we stock a wide selection of industrial-grade sealants that are trusted by trades and technicians across the Mid North Coast. Our range includes high-temperature sealants, anaerobic options, RTV silicone, thread lockers, and flexible adhesives. All are sourced from reputable brands known for strength, reliability, and performance.

Wauchope customers trust our team for practical advice, fast turnaround, and honest support. Whether you’re a mechanic, fabricator, or DIYer, we’ll help match the product to your job.

Contact 02 6552 3699 today to chat with our team or order your preferred sealant.

Bonding, Sealing & Protection

At Mid Coast Bearing Centre, we help customers across Wauchope choose the right sealant for their exact application—whether it’s exposure to heat, chemicals, vibration, or pressure. Our selection includes sealants for automotive engine repairs, construction joints, pipe fittings, and industrial equipment.

We’ll help you understand curing times, application methods, and surface preparation to ensure the best result. Many of our sealants come ready to use in cartridges or tubes, with options that suit both permanent and removable assemblies.

If you’re unsure whether you need a flexible RTV silicone or a rigid anaerobic sealant, we’ll explain the pros and cons of each. Our advice is straightforward, and our product range is suited to both professionals and serious DIY users.

We take pride in helping Wauchope locals get fast access to the right supplies, saving time and money on repeat repairs or poor-quality products. Whatever your sealing job, we’re here to help you do it once and do it properly.

Can a general-purpose sealant be used on engines or mechanical parts?

Using a general-purpose sealant on engines or mechanical components is risky and often leads to failure. These sealants may not tolerate the high temperatures, vibration, or exposure to oil and fuel found in mechanical systems. For automotive engines, you need high-temperature RTV silicone or a manufacturer-approved gasket maker that forms a durable, heat- and oil-resistant seal. For thread sealing, an anaerobic thread locker or sealant is typically recommended. Using the correct product ensures reliability, prevents leaks, and protects surrounding components. Always check the product specifications and compatibility with your application before use.

What’s the best way to prepare a surface before applying sealant?

Proper surface preparation is critical for sealant adhesion and performance. Begin by cleaning the surface thoroughly—remove old sealant, dirt, oil, grease, and moisture using a degreaser or appropriate cleaner. For smooth metal surfaces, a light abrasion with fine sandpaper or a wire brush can help improve bond strength. Ensure the surface is dry before applying the new sealant. If using RTV, allow it to form a “skin” before assembly if required. Anaerobic sealants, on the other hand, work best between tight-fitting clean metal parts. Following these steps will extend the life and effectiveness of your seal.

How long do sealants typically last after application?

The longevity of a sealant depends on the type, application, and environmental conditions. High-quality RTV silicone sealants can last up to 20 years when used correctly, especially in indoor or sealed environments. Anaerobic sealants used in mechanical joints often last the lifespan of the component if installed properly. However, exposure to UV light, constant movement, extreme heat, or corrosive substances can reduce a sealant's life. Regular maintenance checks are recommended, especially in critical systems like engines or pressurised pipework. When sealants begin to crack, peel, or lose adhesion, it’s time to reapply.