Sprockets & Chains in Kempsey

- Fast delivery across the Mid North Coast

- Stocked with trusted, quality brands

- Knowledgeable, hands-on customer support

Request a call back In Kempsey

Thank you for contacting Mid Coast Bearing Centre.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

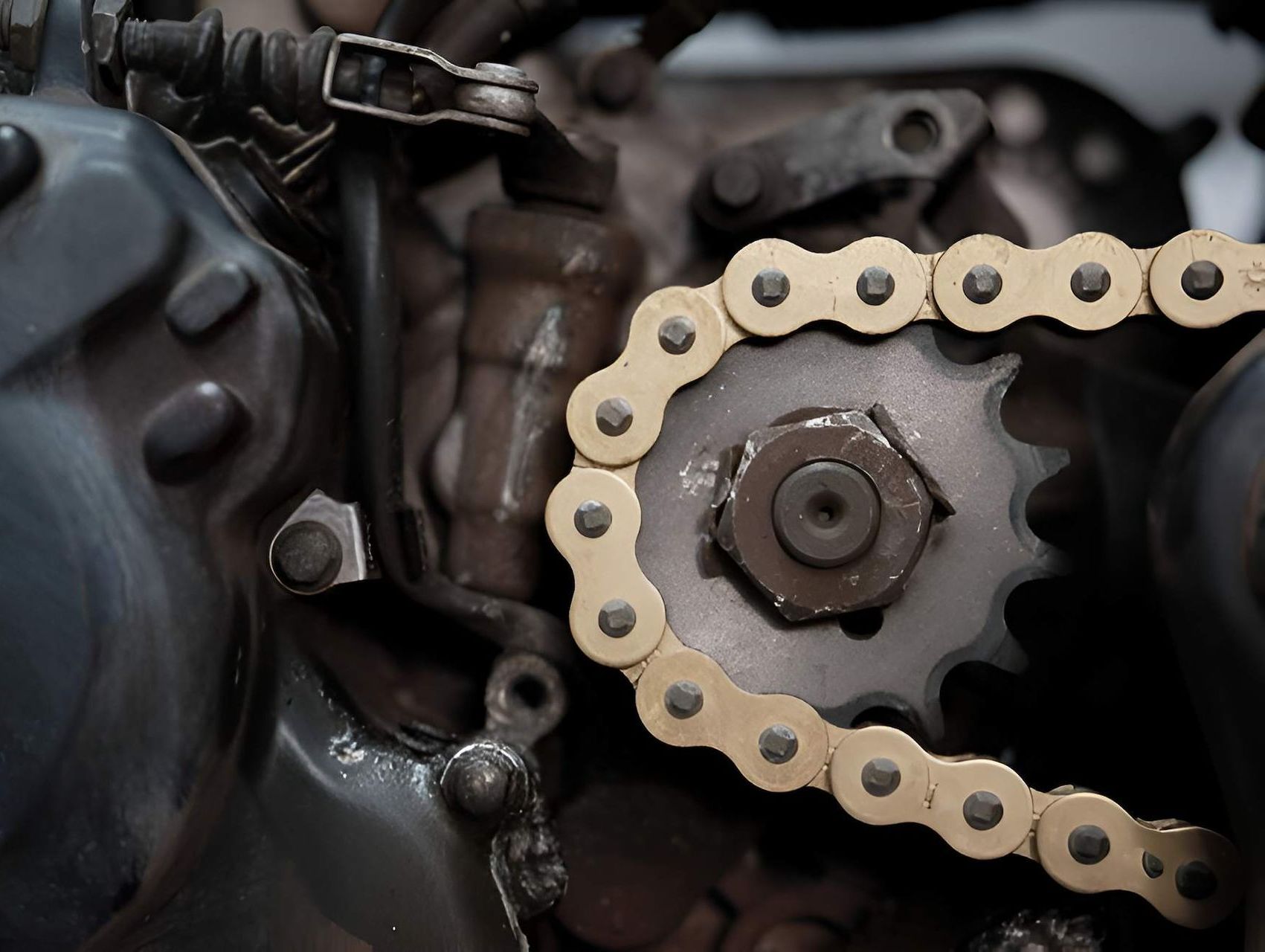

Kempsey Chains & Sprockets

Looking for reliable chains and sprockets in Kempsey? Mid Coast Bearing Centre has been supplying durable, heavy-duty transmission solutions to the Mid North Coast for more than 40 years.

We provide roller chains, link chains, and a variety of sprockets to suit industrial equipment, farm machinery, and workshop tools. Whether you’re maintaining a conveyor system, replacing worn chains on agricultural gear, or upgrading your drive components, we’ll help you find the right match.

Our range includes ANSI, ISO, and specialty sizes for both standard and high-load applications. All products are sourced from trusted brands and chosen for their strength, precision, and durability.

Kempsey customers value our down-to-earth advice and quick supply, especially when dealing with urgent repairs or uncommon parts. We’re here to help identify and supply the exact components you need.

Contact 02 6552 3699 today to speak with the team and ask about our current stock of chains and sprockets.

Built for Local Demands

At Mid Coast Bearing Centre, we support Kempsey’s industries with chains and sprockets that can handle tough workloads and demanding environments. Whether you’re dealing with harvesting equipment, machinery in a timber mill, or a workshop drive system, our team will help you match the right chain and sprocket to your system’s requirements.

We stock single, double, and triple-strand roller chains, plus a variety of sprockets, including pilot bore, taper lock, and split-type. We can also supply joining links, tensioners, and tools to make installation easy.

If you're seeing issues like chain elongation, tooth wear, or uneven performance, we’ll help troubleshoot and suggest a better setup. Kempsey customers benefit from our ability to source both off-the-shelf and hard-to-find parts quickly, helping minimise downtime. With a strong focus on fit, function, and value, we make sure your power transmission components are doing their job safely and efficiently.

What is chain pitch and why is it important?

Chain pitch refers to the distance between the centres of two consecutive pins in a chain. It’s one of the most critical dimensions when selecting or replacing a chain, as it must match the pitch of the sprocket teeth. If the pitch is incorrect, the chain will not sit properly on the sprocket, leading to skipping, wear, or even failure. Common pitches include 1/2", 5/8", and 3/4", and they’re often referenced in ANSI or ISO chain numbers (e.g., 40, 50, 60). Always measure or confirm the pitch when ordering new chains or sprockets to ensure compatibility.

Can I use different chain grades or types on the same sprocket?

Mixing chain types or grades on the same sprocket isn’t recommended, even if they appear to fit. Differences in roller diameter, width, or flexibility can cause improper engagement, increased wear, or uneven loading. For best performance and longevity, always pair chains and sprockets designed to work together—using the same pitch, roller size, and standard (e.g., ANSI, ISO). If you’re unsure, check the existing part number or bring both the chain and sprocket to a supplier for accurate matching.

What causes chains to stretch over time?

Chains don’t actually stretch in the traditional sense. Instead, elongation happens due to wear between the pins and bushings. Over time, this internal wear increases the spacing between links, making the chain appear longer. Excessive elongation causes poor engagement with sprockets, noisy operation, and increased risk of breakage. To prevent this, keep chains properly lubricated, maintain correct tension, and replace them before reaching 1.5% elongation. Measuring chain wear with a ruler or chain wear gauge is a helpful maintenance step.