Sprockets & Chains in Forster

- Fast delivery across the Mid North Coast

- Stocked with trusted, quality brands

- Knowledgeable, hands-on customer support

Request a call back In Forster

Thank you for contacting Mid Coast Bearing Centre.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.

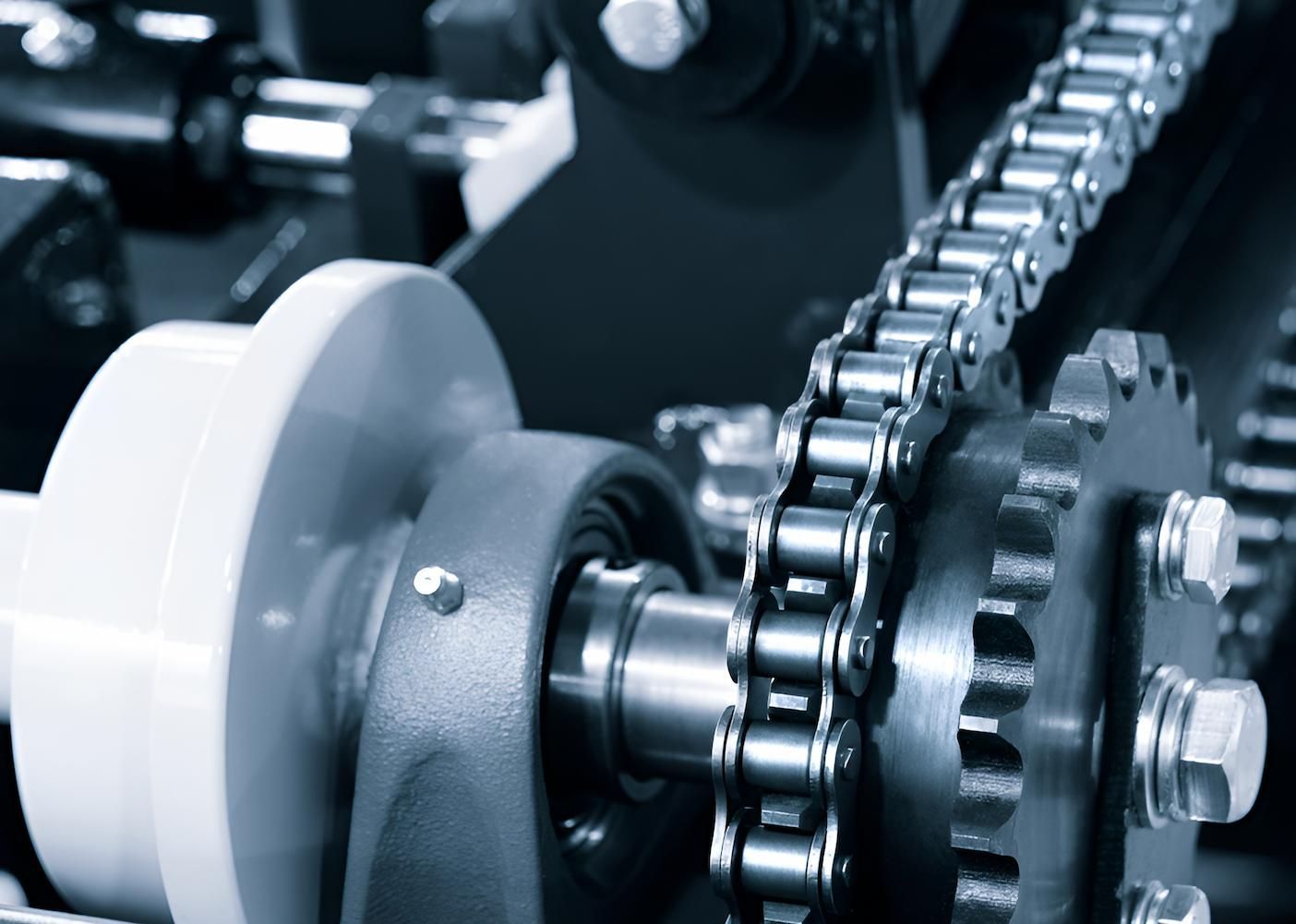

Forster Chains & Sprockets

Looking for reliable chains in Forster? Mid Coast Bearing Centre is your trusted local supplier, offering a wide range of industrial and machinery-grade chains backed by decades of hands-on experience. We proudly support the local farming, automotive, commercial, and construction sectors with strong, long-lasting chains that perform under pressure.

Whether you’re repairing a drive system, upgrading conveyor equipment, or maintaining agricultural machinery, we stock high-quality roller chains in various sizes and styles. Our team understands the equipment used in the Forster area and can help you choose the right solution for your needs.

We only source from reputable manufacturers and test our products for performance, strength, and durability. Customers choose us for our fast service, honest advice, and no-nonsense approach to parts and repairs. With quick delivery and competitive pricing, it’s no surprise we’re the go-to chain supplier in the region.

Contact 02 6552 3699 today to order or learn more about our range of chains.

Heavy-Duty Chains That Last

When it comes to equipment performance, the quality of your chains can make all the difference. At Mid Coast Bearing Centre, we supply Forster locals with dependable chain solutions that are built to handle daily wear and tear in challenging conditions.

Whether it’s driving agricultural equipment, powering construction gear, or managing industrial machinery, we provide chains that are built for strength, longevity, and reliability. We assist customers with selecting the right pitch, length, material, and configuration for their equipment, ensuring proper alignment and smooth operation.

Our range includes standard roller chains, stainless steel options for corrosion-prone areas, and heavy-duty variants for high-load use. We also carry matching sprockets to ensure your system runs at its best.

All orders are carefully prepared and dispatched promptly, with same-day delivery available for Forster. When you need technical support or quick replacements, you can count on our team for clear answers and fast solutions.

What is the purpose of chains and sprockets in machinery?

Chains and sprockets work together to transmit mechanical power across moving parts in a wide variety of machines. The chain connects two or more rotating shafts and wraps around the sprockets, which are toothed wheels that engage with the links of the chain. As the driving sprocket turns, the chain moves and turns the driven sprocket, transferring motion and torque from one point to another. This setup is used in applications like conveyor belts, motorcycles, agricultural equipment, and factory machines. Chains and sprockets are favoured for their ability to handle heavy loads, resist slippage, and deliver consistent power transmission even in dirty or demanding environments.

How do I know what chain size I need?

To select the correct chain size, you'll need to measure or identify several key factors. These include the pitch (the distance between chain pins), roller diameter, and inner width between the inner plates. Chain size is usually identified using a standard numbering system (such as ANSI or ISO), which refers to those measurements. You’ll also want to consider the chain's tensile strength, environmental conditions (e.g. moisture, chemicals), and the speed/load requirements of your machinery. If replacing an old chain, measurements can be taken directly or referenced using the part number. Using the wrong size can result in poor fit, premature wear, or system failure, so it’s important to get accurate sizing from a reliable guide or professional support.

What causes chains and sprockets to wear out?

Several factors contribute to the wear of chains and sprockets. The most common issues include poor lubrication, misalignment, excessive load, and contamination from dust, dirt, or chemicals. Chains may stretch over time due to friction and loading, which can lead to a loose fit and slippage. Worn sprockets often show signs of tooth hooking or uneven wear, which can damage the chain further. Operating machinery with a worn or improperly tensioned chain increases the risk of failure. Regular maintenance—such as proper lubrication, cleaning, and alignment—can significantly extend the life of both chains and sprockets and reduce the risk of costly downtime.